NORH LOUDSPEAKER

If nOrh Loudspeakers only gave careful consideration to the drivers and used quality components to build our crossover, we would be the same as many other companies making loudspeakers. What distinguishes nOrh Loudspeakers from other companies is that we have given particular attention to the cabinet of the loudspeaker.

Many loudspeaker designers will tell you that the crossover is the most important element. I don't believe there is a most important element. I believe that the loudspeaker has to be balanced. However, it is possible to correct many of the problems with the cabinet and with the drivers using a custom designed crossover.

A good cook can make virtually any piece of meat taste good. Yet how many of us knowingly want to eat cheap meat. The reason why we go to fancy restaurants is to see what a good cook can do with a great piece of meet. This is how we view crossovers. The crossover should not try to fix glaring problems with the driver or cabinet. It should be just one more carefully designed element that constitutes the entire system.

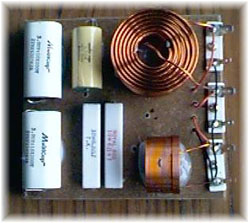

The photo to the right shows the quality of our nOrh 7.0 crossover. It uses three polypropylene capacitors. Two of them are MultiCaps--perhaps the best capacitors. We use air core inductors. These are mounted in a way to avoid crosstalk. The wiring is all silver. We use silver solder. The crossover we use in the nOrh 7.0 is made from the highest quality components. Every nOrh 7.0 crossover is hand wired.

The cheapest loudspeakers simply uses a capacitor to protect the tweeter and use no crossover whatsoever. A crossover requires a specially selected combination of resistance, capacitance, and inductance to cause a smooth transition from the woofer to the tweeter and vice versa. Crossovers are built in many configurations. Generally speaking, simple crossovers provide the smoothest transition. Crossovers should not be overly complicated, as this will detract from the sound.

A very good article on crossovers can be found in John L. Murphy's book "Introduction to Loudspeaker Design". I encourage you to read the article Multi-Way Crossover Design on the True Audio Site.

Many computer programs are available that make the task of designing crossovers seem easy. The problem is that these programs treat drivers as if they are resistors (equal impedance and characteristics for all frequencies). The fact is, loudspeakers change impedance over the entire performance range. Computer programs can only provide a useful starting point. We use WinSpeakerZ's from True Audio to make predictions on how the loudspeaker will behave under different conditions. We then use LMS from Linear to test our predictions.

Note: We want to thank Alan Issakson from DACT for his help. When we first met Alan, he showed us that the crossover we were using was linear and good enough. However, he wanted to help us create a crossover that would be as good as possible matching the components we used. Allan put in many hours to create the crossovers. The nOrh 6.0 and nOrh 6.5 had different crossovers that are carefully tuned providing as close to a seamless interface as possible.

Alan showed us that we had a slight ringing from the sound reverberating off the front of the speaker. We covered the face with rubber and the ringing disappeared.

We even tested our speaker grills. Many people will instinctively remove their speaker grills because it sounds better. The fact is, many speaker grills are poorly designed and hurt the sound. We tested our speaker grill. At no point was the sound impacted by more than 2 dB with the cover on. This shows that for most situations, leaving the grill on will provide excellent performance. However, for critical listening, you can remove the cover.

We also tested the speaker to see how the performance was 30 degrees off axis. The results were quite good. This is important because in most listening situations, you will listen to the speaker off axis.

For those technically inclined the Norh 6 and 6.5 use a 6 dB per octave for the woofer and a 12 dB per octave second order filter for the tweeter (crossing over at 3,000 Hz). The nOrh 5 uses a 6 dB per octave for the woofer and a third order 18 dB per octave, filter for the tweeter (crossing over at 4,000 Hz). The nOrh 7.0 uses a 3rd order crossover with an 18 dB per octave slope. We cross the nOrh 7.0 at 2000 Hz..

Currently, all nOrh crossovers are hand wired and hand assembled. We use imported silver wire to make all our connections. All components are 1%. We use 18 AWG air gap inductors and high quality polypropylene/film capacitors. Everything practical has been done to make sure that the crossover creates a seamless interface between the woofer and tweeter.